Brand Name: BZ

Model Number: BZXMGZJ

Place of Origin: Hebei, China (Mainland)

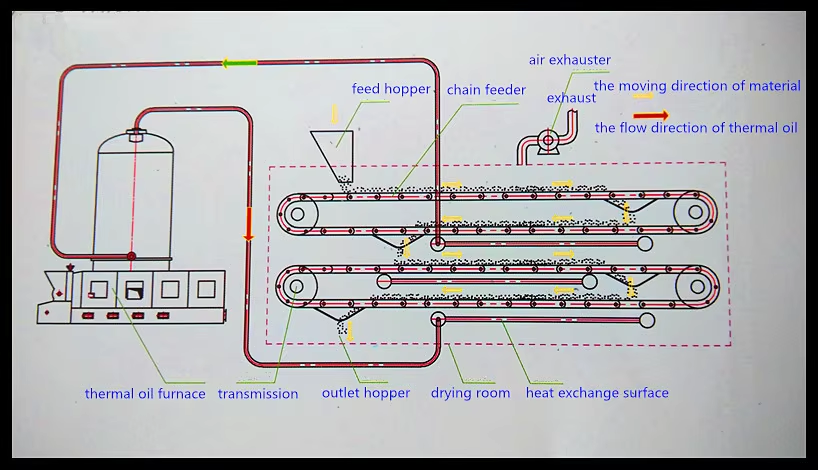

1. The heat needed is provided by thermal oil boiler. The oil circulating pump transfer the heat to heat exchange surface, to dry the briquette on the chain board.

2. The briquette falls on the chain board through feed hopper. When the chain board runs to the depression of rail, the inner roller moves along the down-dip of rail, the briquette is poured on the lower chain board.

The chain board runs along the uplink of the rail through the pull of chain, turn to below by chainwheel, becomes the lower chain board.

It's the same as upper chain board , the briquette is poured on the lower chain board. After severral more circuits, the briquette is sent by discharge hole.

3. The heat exchange area is heat exchange bank of tubes. Except for the first layer of chain board, the heat exchange bank of tubes are arranged under the other chain board.

The thermal oil heated by thermal oil boiler flow s in the bank of tubes, and the heat emanates into the drying room through the bank of tubes, the room temperature is heated up to about 190°c to dry the briquette on the chain board.

The thermal oil comes back to thermal oil boiler and is heated for circulation heating.

4. The gas exhaust adopts air flue and variable frequency conversion blower.

Product feature:

1. Full closed system, low thermal lost, environmental and energy saving, low running cost;

2. The thermal oil as heat carrier, to reach auto-control of temperature, no fire, meet all different

requirements of briquette drying;

3. Even thermal loading, better effect of heat exchanging, the partial temperature won't be too low

or too high;

4. High finished rate of dried briquette, lower broken rate;

5. Adjustable speed motor as power delivery unit, adjust drying time according to the thickness

and water content of briquette, reach best drying effect;

6. The exhaust of gas through frequency conversion blower, avoid raise dust, reduce the drying cost.

| Item | Unit | BZXMGZ-12 | BZXMGZ-22 |

| Processing capacity | t/h | 12 | 22 |

| Heat exchange surface | L(m)*W(m) | 42*1.5 | 50*1.95 |

| Suitable thermal oil furnace | YLL-1200 | YLL-2900 | |

| Thickness of the briquette | mm | 100-150 | |

| Drying time | h | 1.5-2.5 | |

| Drying room temperature | °c | 190 | |

PS: 1. Attributed to the continuous improvement of product peformance, please consult our sales department if you want to learn more about detailed parameters.

2. The drying machine could be customized based on customers' detailed requirements.

1. The lower transportation chain boards should be opened first, then open the upper transportation

chain boards, and no inversion;

2. The exhaust fan should be opened when the briquette starts to be dried.

Company Introduction

Company Introduction

1, Spirit: Supply Reliable & High Efficient Heating System.

2, Produce Capacity: More Than 1000 Sets Of Boilers (5000 T/H) Can Be Produced By us Per Year. Class A Boiler Manufacturer. Class A1, D2 Pressure Vessel Manufacturer.

3, Certification:All products have passed ISO9001:2008 & ASME International Quality Management System Certification, also can provide CE, AS, GOST certification.

4, Business Promise:Each Boiler System Parts Is From First Class Brand All Over The World or China.

5, Quality Strict monitor. From The Material, Welding, To Finished Boiler Shipment; From Project Establishment, Drawing Design, To Final Audit. Advanced automatic welding with 100% passed penetrate X-Ray inspection.

6, User: We Are The Stable And Long Term Supplier Of Many Top 500 Groups All Over The World. Such As PetroChina, Sinopec, Nestle, Mercedes-Benz, Coca Cola, Etc,.

We are looking for long terms cooperation boilerusers,distributors, importers, agents worldwide!

Pre-sale service:

1.According to the customer needs to recommend relative models machine.

2. According to the customer's special requirements to customize equipments.

3. Our engineers will supply the site and equipment drawing.

After-sale service:

1. According to the purchase contract, our company can send engineers to help installation.

2. The quality guarantee is 2 year, not including the wearing parts.

3. Collecting customer feedback, solve the real problems faced by customers.

1. One year warranty;

2. Professional engineers for guiding the stallation, operation and maintanence is available to service machinery overseas.